Sheet Metal Roofing Thickness

(1) Sheet metal roofing shall be not less than,

(a) 0.33 mm thick galvanized steel,

(b) 0.46 mm thick copper,

(c) 0.46 mm thick zinc, or

(d) 0.48 mm thick aluminum.

Article 9.26.13.1. Ontario Regulation 332/12 Building Code, Information published by oncodes.ca for educational purposes only.

Sheet Metal Roofing

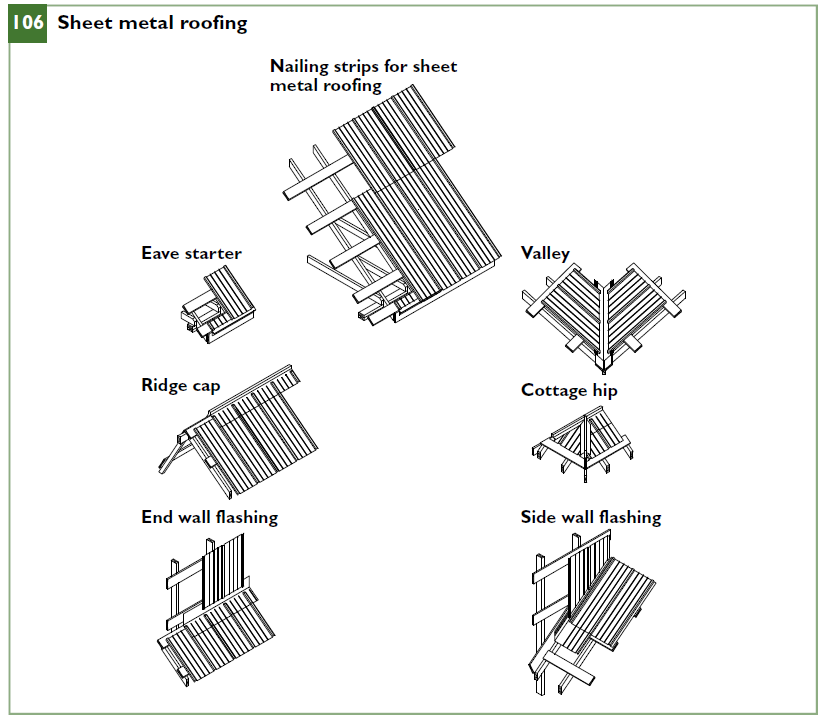

Sheet metal roofing is manufactured in widths from 762 to 914 mm (30 to 36 in.) and in any lengths specified by the builder. Various accessories are needed for hips and valleys, eave starters and edges (Figure 106).

The minimum slope for sheet metal roofing is 1:4, unless the manufacturer provides written confirmation that a lower slope has been tested and proven. If sheet metal roofing is applied over spaced supports, the sheets need to be designed to support the snow load, and there must be a support under each end joint (Figure 106).

The choice of metal thickness, whether steel or aluminum, depends on the local snow load and the profile of the metal roofing, but should not be less than 0.33 mm (0.013 in.) for galvanized steel, 0.46 mm (0.018 in.) for copper or zinc and 0.48 mm (0.019 in.) for aluminum. The required thicknesses for specific snow loads are provided by the manufacturer.

Figure 106

Source : Canada Mortgage and Housing Corporation (CMHC)