Installing Roof Sheathing

When plywood or OSB is used for roof sheathing, sheets are laid with the face grain at right angles to the framing (Figure 97) and with the joints offset to obtain a good tie across the roof framing. Leave a 2 to 3 mm (1⁄8 in.) gap between panels to prevent buckling should expansion in the sheathing occur.

Sheathing thickness depends on the spacing of the rafters, roof joists or trusses and whether the edges of the sheets are supported. To prevent damage to the roof covering when thinner panels are used, support the joints with 38 × 38 mm (2 × 2 in. nominal) blocking nailed securely between the roof framing members, or by metal H-clips inserted between sheets. H-clips are widely used because installation is simple and economical.

It is good practice to stagger the location of fasteners at the edges of adjoining panels. Staple fasteners for 9.5 mm (3⁄8 in.) roof sheathing must be at least 1.6 mm thick, 38.1 mm long with a 9.5 mm crown (1⁄16 in. thick, 11⁄2 in. long with a 3⁄8 in. crown), and be driven with the crown parallel to the framing. Thicker roof sheathing no less than 15.5 mm (5⁄8 in.)—is required for built-up roofing on a low-slope roof to be used as a walking deck.

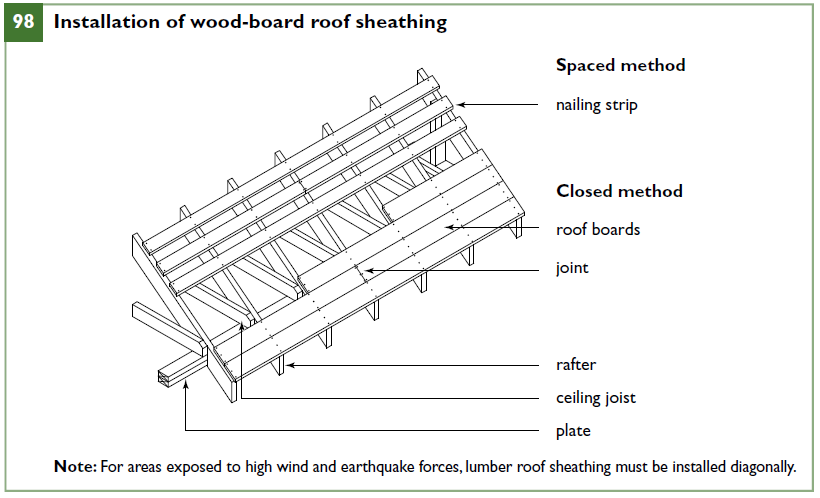

Lumber sheathing must be laid closed, or edge to edge (Figure 98) with all ends supported and joints staggered. For exposure to high wind or earthquake forces, lumber sheathing must be laid diagonally or be engineered. The boards are usually 19 mm (¾ in. nominal) thick, but this thickness may be reduced to 17 mm (11⁄16 in.) where supports are spaced at 400 mm nominal (16 in. actual) or less on centre.

Figure 98

Boards 184 mm (8 in. nominal) or less in width are nailed to the framing members with at least two, 51 mm (2 in.) nails per bearing. Those wider than 184 mm (8 in. nominal) should be nailed with at least three, 51 mm (2 in.) nails per bearing. For areas with high wind loads, the length of the nails must be increased to 63 mm (21⁄2 in.).

Boards wider than 286 mm (12 in. nominal) should not be used for roof sheathing. For a wood shingle roof, the roof boards may be spaced the same distance apart on centre as the shingle exposure. This method (Figure 98), commonly used in damp climates, permits air movement and allows shingles to dry between wettings, reducing the possibility of decay.

Source : Canada Mortgage and Housing Corporation (CMHC)