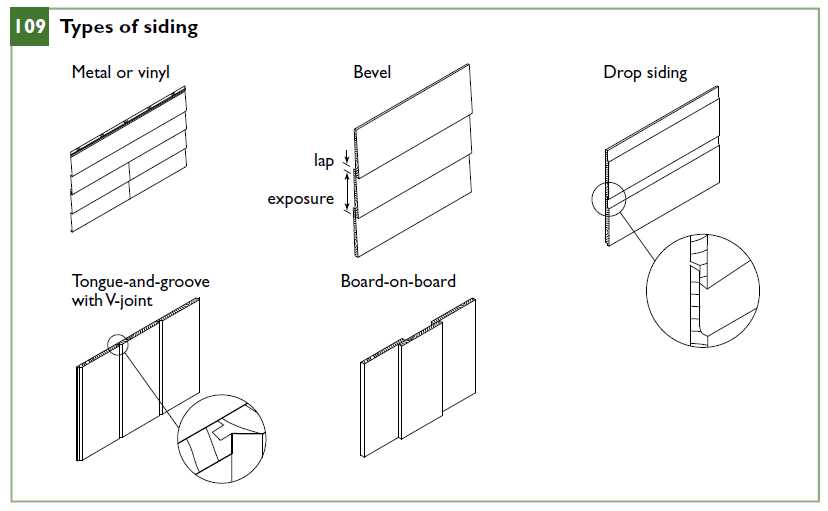

Metal and Vinyl sidings

Metal and vinyl sidings are factory finished and manufactured in many shapes and patterns. They are made to interlock so that only the upper side of the siding is nailed, while the bottom edge is locked to the upper part of the siding strip below (Figure 109). Interior and exterior corners, termination points of the soffit and gable ends as well as windows and doors, are covered using specially designed trim pieces.

Horizontal Application

Prepare the wall for cladding by applying the sheathing membrane. In wet and humid coastal climates, strapping (furring) is required to provide a vented space (rainscreen) to facilitate drainage and drying. Establish a level line around the house for the starter strip, which is normally placed a minimum of 150 to 200 mm (6 to 8 in.) above finished grade. Install all trim pieces for corners, windows, doors and openings and starter strips; and then apply the siding in successive courses up to the underside of the soffit.

Laps of adjacent strips of siding should be staggered more than 600 mm (24 in.) apart and should all face in the same direction away from the general viewing angle. Install metal and vinyl siding so that it can expand and contract with temperature changes without buckling, and make sure to follow the manufacturer’s installation instructions. Place nails in the centre of the nail slots, and do not hammer them tight to the wall.

Vertical Application

Apply the sheathing membrane to prepare the wall for cladding. Some types of metal and vinyl siding can be applied directly over the sheathing membrane. In locations that require a rainscreen, the strapping (furring) should be applied horizontally and spaced according to the siding manufacturer’s recommendations. Provide 10 mm (3⁄8 in.) gaps between the butt ends of the strapping to allow water behind the cladding to drain downwards and out of the wall.

Figure 109

Oncodes.ca publishes this information for educational purposes only (CMHC)