(1) Where the air barrier system consists of an air-impermeable panel-type material, all joints shall be sealed to minimize air leakage.

(2) Where the air barrier system consists of flexible sheet material, all joints shall be,

(a) sealed with compatible material such as tape or flexible sealant, or

(b) except as required by Sentence (3), lapped not less than 100 mm and clamped, such as between framing members, furring or blocking and rigid panels.

(3) Where an air barrier system consisting of flexible sheet material is installed at locations where it is not supported by an interior finish, such as a behind a bath tub, shower enclosure or fireplace, the continuity of the air barrier shall be maintained by sealing its joints.

(4) Where an interior wall meets an exterior wall, ceiling, floor or roof required to be provided with an air barrier protection, the air barrier system shall extend across the intersection and shall be sealed in accordance with Sentences (1) and (2).

(5) Where an interior wall projects through a ceiling or extends to become an exterior wall, spaces in the wall shall be blocked to provide continuity across those spaces with the air barrier system in the abutting walls or ceiling by,

(a) sealing each air barrier to the blocking, or

(b) wrapping each air barrier around the transition and sealing in accordance with Sentences (1) and (2).

(6) Where an interior floor projects through an exterior wall or extends to become an exterior floor, continuity of the air barrier system shall be maintained from the abutting walls across the floor assembly.

(7) Where an interior floor projects through an exterior wall to become an exterior floor,

(a) the air barrier of the wall under the floor shall be continuous with or sealed to the subfloor or the air barrier on the underside of the floor,

(b) the air barrier of the wall above the floor shall be continuous with or sealed to the subfloor or the air barrier on the top of the floor, and

(c) the spaces between floor joists shall be blocked and sealed.

(8) Where a header wrap is used as an air barrier, it shall be sealed or lapped to the wall air barrier above and below in accordance with Sentences (1) and (2).

(9) Penetrations of the air barrier system, such as those created by the installation of electrical wiring, electrical boxes, piping or ductwork, shall be sealed with compatible material such as tape or caulking to maintain the integrity of the air barrier system over the entire surface.

(10) Penetrations of the air barrier system, such as those created by the installation of doors, windows and other fenestration shall be sealed to maintain the integrity of the air barrier system over the entire surface.

(11) Where an interior air barrier is penetrated by doors, windows and other fenestration, the air barrier shall be sealed to the door frame or window frame with,

(a) compatible tape, or

(b) spray foam insulation.

(12) Where an exterior air barrier is penetrated by doors, windows and other fenestration, the air barrier shall be sealed to the door frame or window frame with,

(a) compatible flexible flashing material,

(b) caulking, or

(c) spray foam insulation.

(13) An access hatch installed through an assembly constructed with an air barrier system shall be weatherstripped around the perimeter to minimize air leakage.

(14) Clearances between chimneys or gas vents and the surrounding construction that would permit air leakage from within the building into a wall or attic or roof space shall be sealed by noncombustible material to prevent such leakage and shall be sealed to the air barrier with tape or another compatible material, and to the vent with high temperature caulking in accordance with the manufacturer’s installation instructions.

(15) Where the foundation wall and floor slab are used as an air barrier, they shall be caulked at all joints, intersections and penetrations.

(16) Sump pit covers shall be sealed to maintain continuity of the air barrier system.

Article 9.25.3.3. Ontario Regulation 332/12 Building Code, Information published by oncodes.ca for educational purposes only.

Air Barrier System

The NBC stipulates that the building envelope must be designed and constructed with a continuous air barrier system comprised of air barrier assemblies to control air leakage into or out of the conditioned space. Air leakage control requires a continuous air barrier system carried through the basement floor and walls, above-grade exterior walls and ceilings adjacent to roofs. Air leakage control within building envelope assemblies can be accomplished by incorporating materials with low air permeability, which are fairly common in house construction.

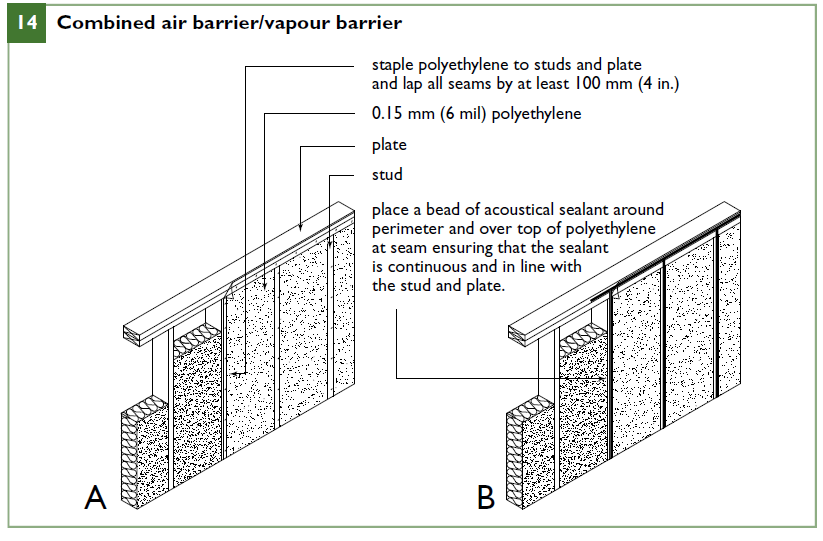

However, joints and penetrations must also be sealed to stop air leakage, and the air barrier must be supported to prevent deformation or tearing. Polyethylene sheets are commonly used as an air barrier in wood-frame construction and are relatively easy to secure, seal and support on wood framing. In addition to polyethylene sheets, other materials such as spun-bonded polyolefin, gypsum board, sealants, gaskets, spray-applied foam, rigid insulation, concrete, plywood or OSB sheathing, metal and glass can be used as part of the air barrier. All joints, connections and penetrations must be sealed using tapes, gaskets, foams, sealants and membranes in order for the building envelope to be airtight.

Source : Canada Mortgage and Housing Corporation (CMHC)